SORTATION SOLUTIONS

CASI Sortation Solutions provides measurable efficiency gains for both labor utilization and operational efficiency.

HOW CASI SORTATION SOLUTIONS WORK

CASI’s wide range of package sorter technology allows our customers to fully realize the exponential savings in labor cost, an automated package sortation system can provide. CASI’s flexible sorting product types have proven to be an efficient, high-volume and cost-effective essential solution in any automated warehouse application.

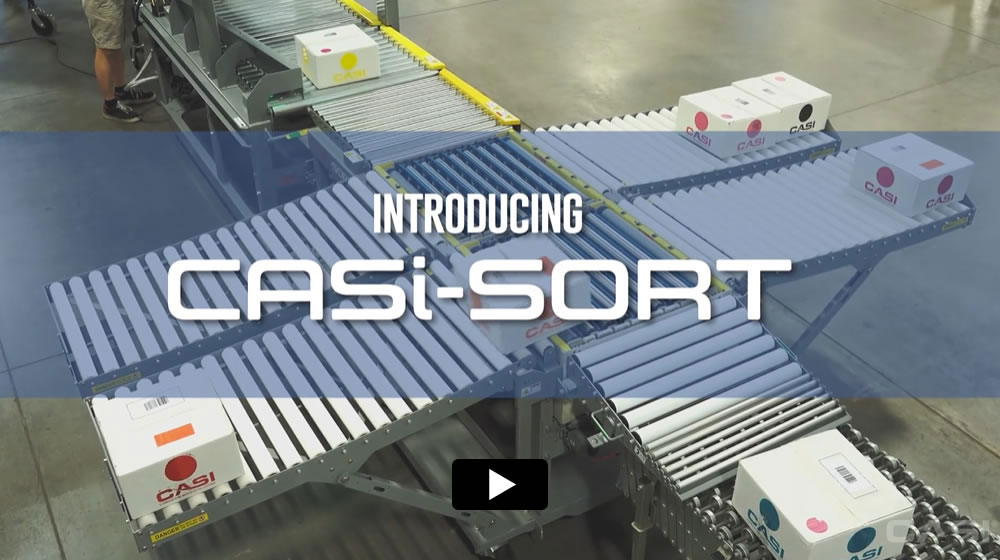

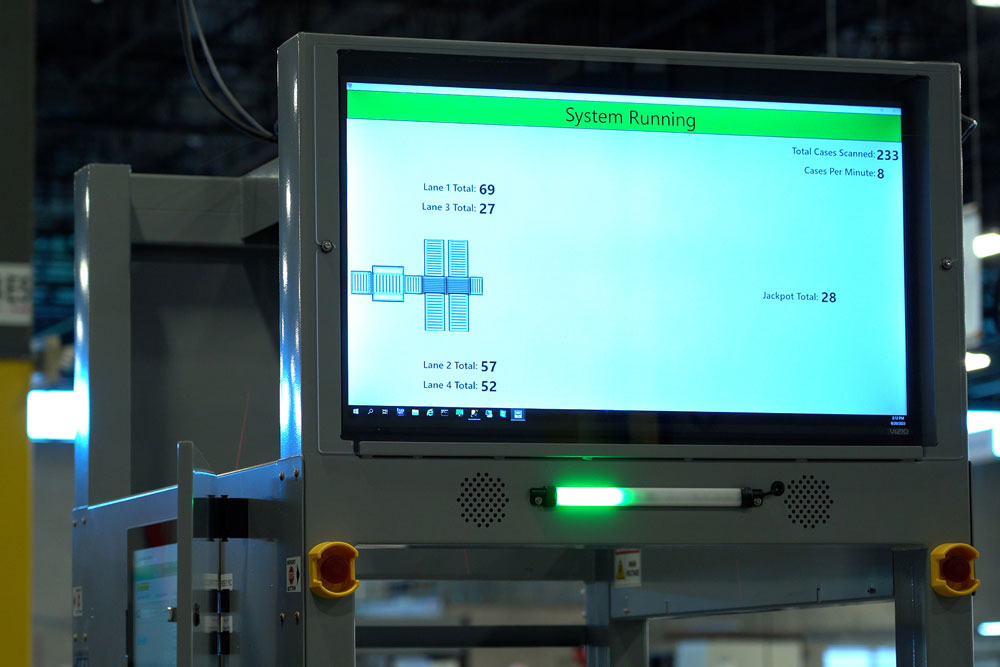

CASi-SORT is a smart sortation solution for any receiving area that processes high-volume truck loads on a daily basis.

- Priority Sorting: Customize and prioritize sort locations in real-time.

- Labor Optimization: Automate one of the most time-consuming and error-prone aspects of inbound and outbound processes – verification, documenting and sorting.

- Reduce Shrinkage: Scanning each product on arrival provides a quick and easy way to monitor the expected vs. actual shipments.

- Save Space: When not in use, CASi-SORT’s wings easily fold up to reduce the system’s footprint.

A compact footprint adaptable to almost any backroom, the CASi-FlashSort® includes nearly limitless sortation possibilities.

- Easy to Use: Wheels allow for mobility; requires minimal training

- Unlimited Sortation: The digital displays give you infinite sortation possibilities that can dynamically change based on needs

- Space: Narrow footprint for backrooms with limited space

- Low Maintenance: Fewer mechanical components makes for less ongoing maintenance

- Labor Optimization: Maximize existing labor while increasing efficiency

- Low Cost: Simple and smart automation for a fraction of the cost of a fully automated solution